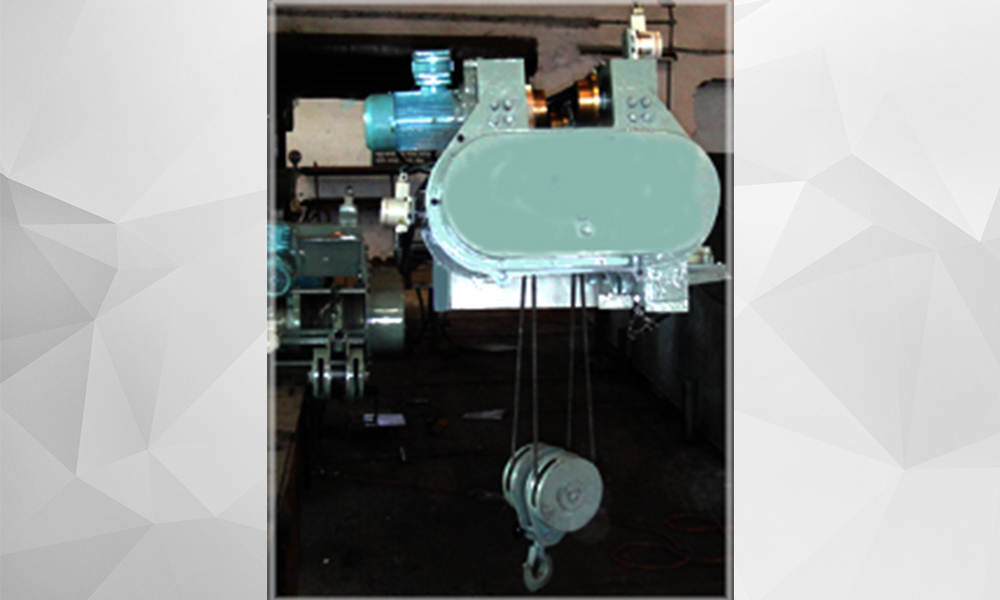

Hi-Tech Flame proof Hoist :

GENERAL SPECIFICATION FOR FLP HOIST :

- The drive shall consist of flame proof motor, brakes, limit switches and push button stations.

- All electrical fittings shall be flameproof suitable for group IIA and IIB vapour.

- Flame proof limit switches for extreme ends in horizontal and vertical movement.

- Inching facility (for up & down motion as well as forward & reverse motion).

- Flame proof local control panel housing.

- Main incoming isolator.

- Contactor, relays, fuses etc.

- Overload and short circuit protection for motors.

ELECTRICALS :

Power Cables shall be 1100 v grade, PVC insulated, GI armoured & PVC overall sheathed. Conductor shall be of copper below 10mm2 & for sizes above 10mm2 cables shall be XLPE / SWA. Control cables shall be multistrand copper conductors of minimum 2.5 sq. mm. All motors shall conform to squirrel cage induction motors, TEFC, IP – 55, Class ‘F’ insulation, flameproof suitable for Group IIA & IIB vapour, CMRS certified.

MECHANICALS :

All metal-to-metal contact are of non-ferrous i.e. phospherous bronze like cross travel wheels.

INSPECTION AND TESTING :

- The hoist shall be offered for final inspection.

- Client / authorised representative shall at all times have an access to supplier’s / suppliers sub contractors workshop to witness fabrication stages.

- Internal inspection record shall be maintained by supplier / suppliers sub contractor at all times, if any stages are found lacking by way of proper records. Client reserves, the right to ask supplier to modify / amend the fabrication stage.