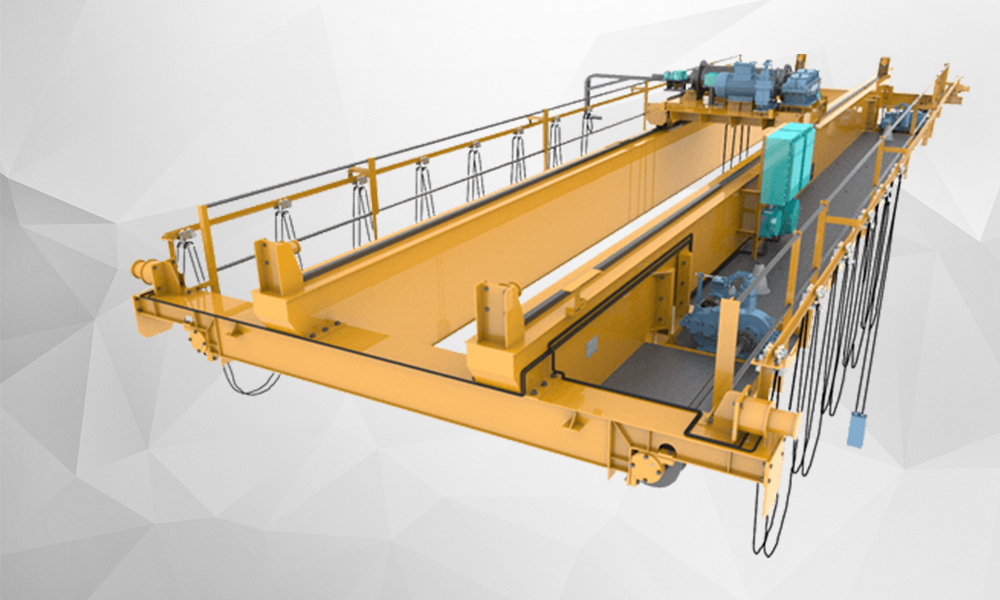

Hi-Tech Flame proof Crane :

GENERAL SPECIFICATION FOR FIRE PROOF CRANE :

- The drive shall consist of flame proof motor, brakes, limit switches and push button stations.

- All electrical fittings shall be flameproof suitable for group IIA and IIB vapour.

- Flame proof limit switches for extreme ends in horizontal and vertical movement.

- Inching facility (for up & down motion as well as forward & reverse motion).

- Flame proof local control panel housing.

- Main incoming isolator.

- Contactor, relays, fuses etc.

- Overload and short circuit protection for motors.

ELECTRICALS :

Power Cables shall be 1100 v grade, PVC insulated, GI armoured & PVC overall sheathed. Conductor shall be of copper below 10mm2 & for sizes above 10mm2 cables shall be XLPE / SWA. Control cables shall be multistrand copper conductors of minimum 2.5 sq. mm. All motors shall conform to squirrel cage induction motors, TEFC, IP – 55, Class ‘F’ insulation, flameproof suitable for Group IIA & IIB vapour, CMRS certified.

MECHANICALS :

All metal-to-metal contact are of non-ferrous i.e. phospherous bronze like cross travel wheels.

INSPECTION AND TESTING :

The Crane shall be offered for final inspection. Client / authorised representative shall at all times have an access to supplier’s / suppliers sub contractors workshop to witness fabrication stages. Internal inspection record shall be maintained by supplier / suppliers sub contractor at all times, if any stages are found lacking by way of proper records. Client reserves, the right to ask supplier to modify / amend the fabrication stage.

Specific Design Advantages of “Hi-Tech” Flame proof Crane

Design :

“Hi-Tech” Cranes are designed as per lates IS:3177, 807 & 2148.

Modular Construction :

“Hi-Tech” Cranes are very compact with elegant appearance. Crane motor, brake, electrical control gears & trolley drive Unit are easily accessible. Each unit can be separately assembled and can be easily dismantled. This simplifies repairs, maintenance cost and down time.

Gear Boxes :

The gear train is precision hob cut from alloy steel material duly heat treated for optimum wear resistance. The gears are running on antifriction ball bearing in a totally enclosed oil bath gear box with splash lubrication of all gears & pinions for fast heat dissipation, smooth operation and long life.

Rope Drum :

The rope drum is of sturdy construction made of M.S. Seamless pipe and machined cut spiral grooves mounted on self-align ball bearings ensure smooth running.

Rope Guide :

A rope guide completely encircling the drum is to hold the rope in its groove at all the times and can not uncoil even-when the rope is fully unloaded. Rope guide is provided for perfect winding for rope in drum groove.

Motor :

Motor are totally enclosed, fan cooled, squirrel cage crane duty confirming to IS : 325 with high starting torque.

Brake :

A. C. Electromagnetic FAIL-TO-SAFE shoe/disc type brake for hoisting motion which ensures perfect safety in case of power failure. It is mounted externally on the rear end of the motor for ease of maintenance.

Limit Switch :

Snap action type roller limit switches are provided to avoid over-hoisting and over lowering actuated by rope guide.

Control Panel :

A dust & vermin proof control panel incorporates heavy duty Contactors, control transformers, relays, HRC fuses with proper ferruling & spacious for ease of maintenance.